| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Y |

| Model Number : | D342X-10Q |

| Price : | Negotiable |

| Payment Terms : | T/T |

| Supply Ability : | 100000 pcs per month |

| Delivery Time : | 5-8 work days |

The valve has been widely used in the fields of petrochem, ght industry, metallurgy, shipping, power, applingand draining water indrstry pharmary etc. It flowing agents include all of corrosive and uncorrosive gasliquid, seme-liquid. It can adjust and cut off the fluid. On the basis of the single eccentric butterfly valve further improved molding is the most widely used double eccentric butterfly valve. The structure of the valve stem axis deviates from the center of the disc and the center of the body. The effect of double eccentricity enables the disc to be quickly detached from the seat after the valve is opened, greatly eliminating the unnecessary excessive extrusion and scratching phenomenon between the disc and the seat, reducing the opening resistance, reducing wear, and improving the seat life

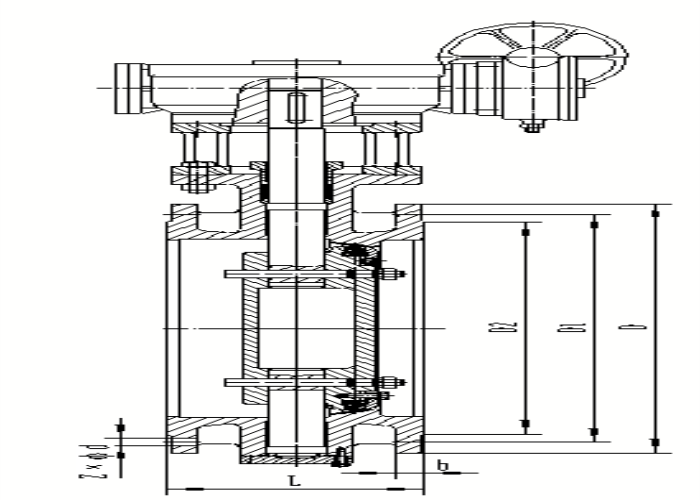

| DN | D | D1 | D2 | b | L | Z-Φd |

| 400 | Φ565 | Φ515 | Φ480 | 216±2 | 16-Φ28 | |

| 450 | Φ615 | Φ565 | Φ530 | 222±2 | 20-Φ28 | |

| 500 | Φ670 | Φ620 | Φ582 | 229±2 | 20-Φ28 | |

| 600 | Φ780 | Φ725 | Φ682 | 267±2 | 20-Φ31 | |

| 700 | Φ895 | Φ840 | Φ794 | 292±3 | 24-Φ31 | |

| 800 | Φ1015 | Φ950 | Φ901 | 318±3 | 24-Φ34 | |

| 900 | Φ1115 | Φ1050 | Φ1001 | 330±3 | 28-Φ34 | |

| 1000 | Φ1230 | Φ1160 | Φ1112 | 410±3 | 28-Φ37 | |

| 1200 | Φ1455 | Φ1380 | Φ1328 | 470±3 | 32-Φ40 | |

| 1400 | Φ1675 | Φ1590 | Φ1530 | 530±4 | 36-Φ43 | |

| 1600 | Φ1915 | Φ1820 | Φ1750 | 600±4 | 40-Φ49 | |

| 1800 | Φ2115 | Φ2020 | Φ1950 | 670±4 | 44-Φ49 | |

| 2000 | Φ2325 | Φ2230 | Φ2150 | 760±4 | 48-Φ49 | |

| Flange end | GB/T 17241.6 |

| Face to face | GB/T 12221 |

| Design and manufacture standard | GB/T12238 |

| Inspection and testing | GB/T13927 |

| Nominal Pressure | 1.0MPa |

| Suitable temperature | ≤80℃ |

| Suitable medium | water |

| Body | Grey iron, Ductile iron |

| Disc | Ductile iron |

| Stem | carbon steel / stainless steel |

| Seal Ring | NBR/ EPDM |

1. The valve adopts double eccentric structure, which has the sealing function that the closer the valve is closed, and the sealing performance is reliable.

2. The butterfly plate sealing ring is made of NBR T-type rubber sealing ring and is firmly installed on the butterfly plate with a pressing plate. After a period of use, the rubber sealing ring is worn out, and the pressure of the rubber sealing ring can be adjusted by tightening and loosening the screws to make the butterfly valve continue to seal without leakage and extend the service life. After the valve is installed, it can be easily adjusted or replaced in the pipeline (without removing the valve from the pipeline).

3. The butterfly plate has high strength, large flow area and small flow resistance.

4, the valve shaft is sealed with O-type rubber packing, the higher the medium pressure, the better the sealing. After the packing is worn, compensation can be obtained by continuing to press the packing gland.

1. The valve is worm gear drive flange connection, double eccentric soft sealing butterfly valve, that is, the stem rotation center of the valve body diameter axis and valve seat sealing surface formed eccentricity. The valve is composed of valve body, disc, stem, seal plate, pressure ring, cochlear moving device and other parts.

2. Cochlear operation: rotating the cochlear hand wheel makes the valve stem rotate 90° and drives the butterfly plate to rotate 90°, so as to realize opening or closing. Because the product is double eccentric structure, can produce a CAM effect in the process of opening and closing, reduce the valve switching torque, reduce the wear between the valve seat and the butterfly plate, prolong the service life of the valve.

9.1 Indoor: The packing room shall be oiled and opened and closed once every 1-2 months when the product is installed indoors.

9.2 Outdoor: When the product is installed outdoors, protective measures should be added to avoid corrosion of the cochlear moving head. The packing room should be oiled and opened and closed once every 1-2 months; Fill the room again after each rain and snow filling and open and close once.

9.3 Downhole: The packing room shall be filled with oil and opened and closed once every 1-2 months when the product is installed downhole; After every rain and snow, the rainwater stored in the well should be pumped out to prevent the products and the cochlear moving head from rusting after soaking the rainwater for a long time. The packing room should be filled with oil and opened and closed once.

9.4 According to different actual working conditions, different cochlear actuators can be selected. Outdoor and underground cochlear actuators can be closed, which shall be specified in the order.

|